Case Studies

Our solutions unlock the power of intelligence in codes to help our customers achieve all of the above and more, end-to-end throughout their supply chain.

Coding that keeps up the pace!

The French subsidiary of Coca-Cola European Partners (CCEP) chose Markem-Imaje laser coders for marking aluminum cans at its Marseille facility. The technology convinced this very large European beverage producer whose production rate can be truly impressive: up to 25 cans a second!

Ambassador of the Italian way of life

The operational partnership between the largest Italian beverage company and Markem-Imaje embraces all coding technologies and types of packaging, from laser to inkjet to print and apply labeling systems. For Sanpellegrino, the goal is product excellence and guaranteed consumer safety.

When tradition meets modernity

Save time, reduce the risk of errors, clearly identify products and guarantee technical reliability: these were the specifications defined by Sabarot for its identification purposes. In addition to other Markem-Imaje products, the 2200 print and apply system and CoLOS software addressed all of these expectations.

Over one million codes printed with not one error

The Gruppo Sada, an Italian leader in the production and transformation of corrugated cardboard, has chosen Markem-Imaje as their partner to meet their customers’ coding and traceability requirements. This collaboration successfully met Birra Peroni’s requirements for promotional coding on their cardboard boxes for a prize contest.

Innovative solution helps print missing codes

When Peak Pipe Systems Ltd, one of the UK’s largest manufacturers and suppliers of high quality polyethylene pipe, contacted Markem Imaje to help code a length of pipe already on site, it was clear that the job would require a flexible approach.

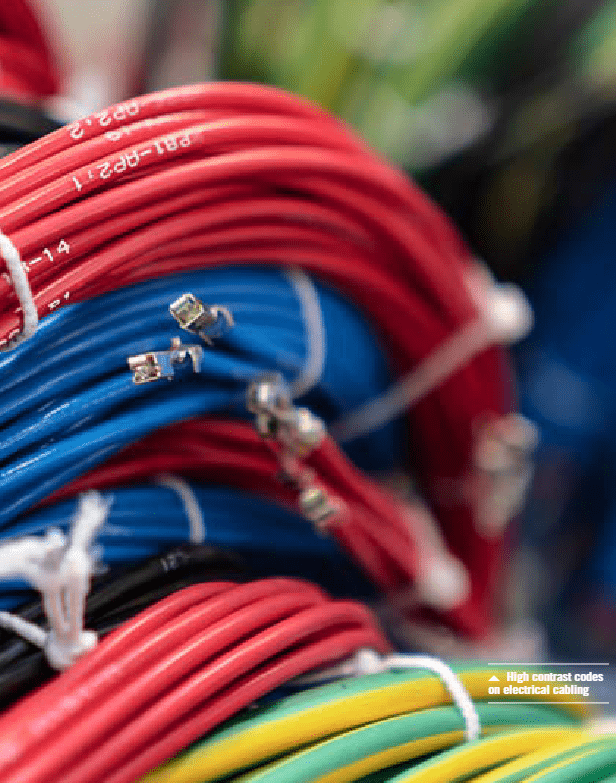

Reliability – Electrical cabling

One of the world’s largest and most respected suppliers of electrical control systems, cable harnesses and sub-contract manufacturing solutions, PP Control & Automation has installed two Markem-Imaje continuous inkjet printers, to print codes on the electrical cabling which the company installs in a wide variety of machinery and other applications.

Over a century of sustainable and organic products.

German organic FMCG brand Töpfer focuses on reducing environmental impact in its packaging. It uses technologies like the 9450 Continuous Inkjet, SmartDate® X40/X60 TTO, 5800 Touch Dry® HR Inkjet, 2200 Pallet, and CoLOS® Packaging Intelligence software.

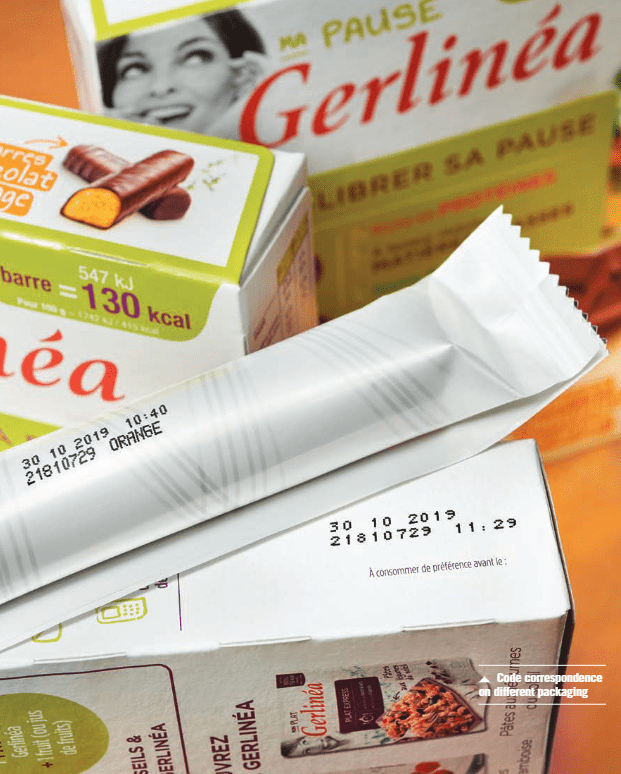

The demand for perfection

Since its take-over by a Japanese pharmaceuticals group in 2009, Nutrition & Santé has stepped up its traceability needs with one essential requirement: a guarantee to deliver “zero marking error” products. Markem-Imaje provided the solution with its Mark & Read system. Read more about it.

Increasing production whilst

implementing eco-design

were the main considerations for Bioplants, France’s top organic herb producer when seeking its coding solutions partner. Markem-Imaje’s 5800 TouchDry® High Resolution inkjet printer and CoLOS® Packaging Intelligence software provided the answer to the company’s sustainability and growth needs.

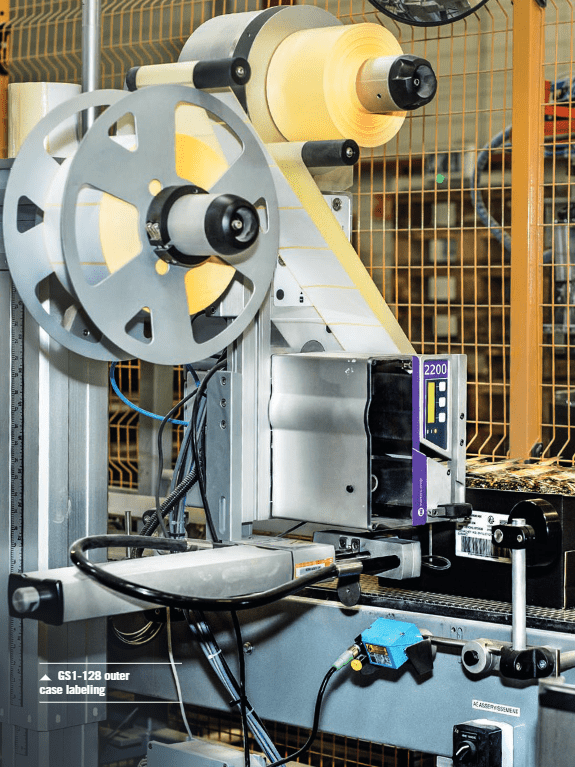

Bel cheeses move to GS1-128 labelin

Reliability, ease of use, software compatibility… The benefits offered by Markem-Imaje’s 2200 printing and label application system have won over the Bel Group, which has adopted it for a number of its cheesemaking plants in Europe. The solution has allowed Bel to create a new labeling standard that includes the GS1-128 barcode symbol.